FYID Laser

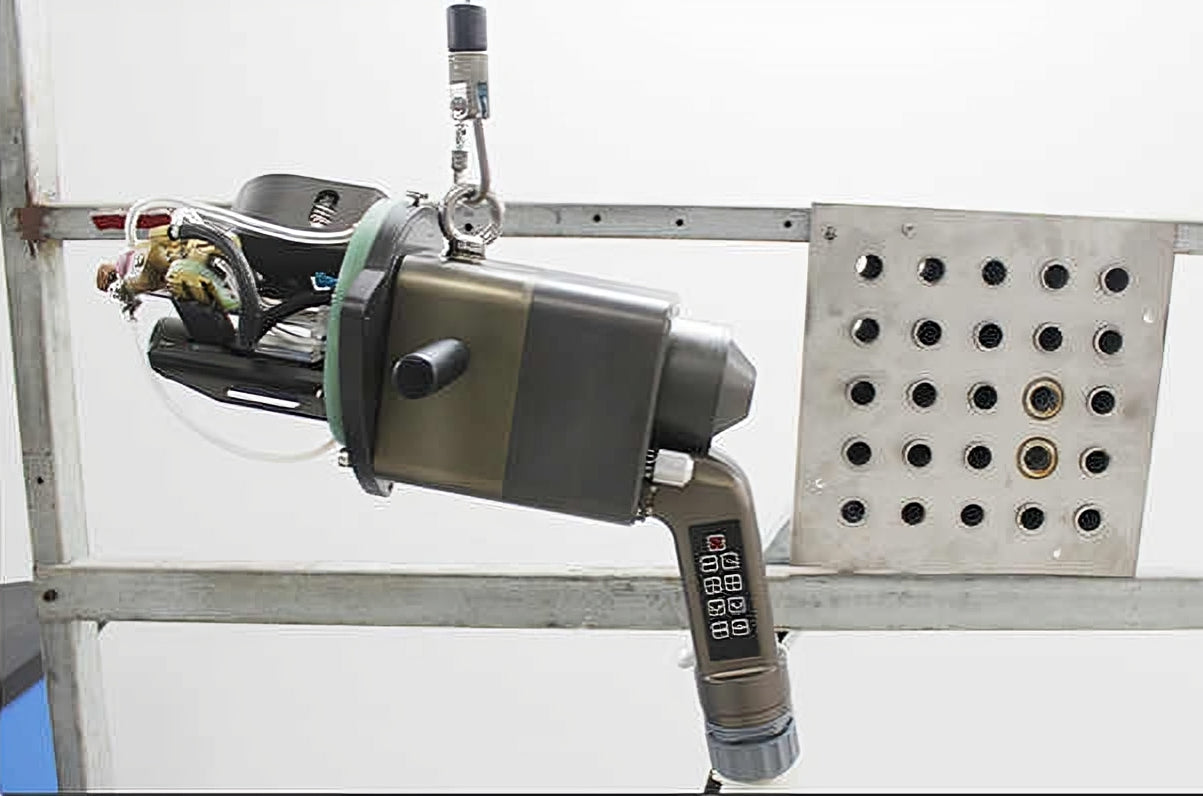

Modern China All-position Tube and Plate Welding Torch Material for Boiler Manufacturing Tube Plate Automatic Welding Gun

Modern China All-position Tube and Plate Welding Torch Material for Boiler Manufacturing Tube Plate Automatic Welding Gun

Precio habitual

$8,290.00

Precio habitual

Precio de oferta

$8,290.00

Precio unitario

/

por

No se pudo cargar la disponibilidad de retiro

Product Introduction

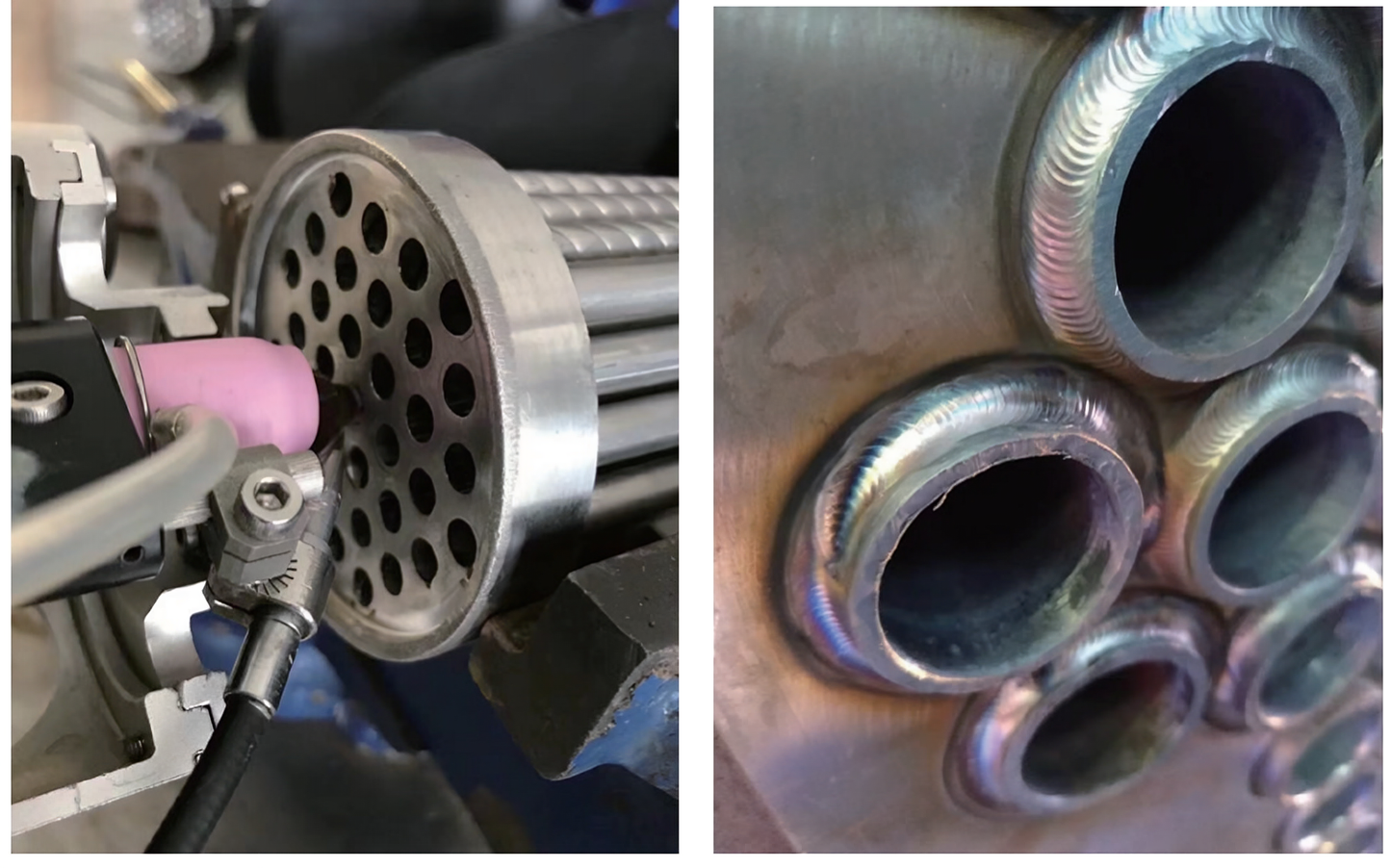

This machine is a special head designed for automatic TG welding of pipe/pipe sheet, adapting to the automatic welding of general pipe sheet forms. It can weld carbon steel, stainless steel and other pipe/sheet joints, including flush end joints and protruding angle joints. Pipe diameter range of 16 ~ 80mm, you can choose to use self-melting, filling wire or first self-melting after filling wire and other welding processes, fast, labour-saving. (When welding 16mm tube - plate, need to replace the random parts of the small gun head; such as do not need to add wire to remove the wire feed motor assembly and wire feed box welding perspective better).

The drive of the head adopts imported hollow cup DC servo motor, stepless speed regulation within the speed range. All the pipes and wires of water, electricity and gas are tangle-free.

Mainly divided into five major parts

A:Power driving part

B:Pneumatic clamping part

C:Arc length control part

D:Gun head part

E:Wire feeding part

Applications:Boiler, chemical industry, heat exchange, air conditioning, nuclear power

|

Parameters

|

||

|

Welding handle model

|

PT40

|

PT80

|

|

Matching Power Supply

|

ET200/M200

|

M400

|

|

Welding pipe diameter range(mm)

|

Φ16~Φ38

|

Φ16~Φ80

|

|

Torch angle

|

0°or 7°

|

0°-30°

|

|

Wire feeding function

|

No

|

Yes

|

|

Cooling method

|

water cooling

|

water cooling

|

|

Weight(kg)

|

3

|

13

|

|

Overall Dimension(mm)

|

150x70x155

|

160x100x170

|

Product Features

ET200/M200 digital program-controlled welding power supply is composed of control system, power supply system and cooling water

tank, which has the characteristics of digitization, easy operation and reliability. The control system adopts an open and upgradeable operating system to centrally set, store and synchronize the various functional parameters in all-position welding.This power supply is specially designed and manufactured for thin-walled tube/tube welding. Mainly used in semiconductor,chemical, food, medicine, electronic pipeline and other industries.The overall design tends to be convenient,energy-saving,intelligent, human-computer interaction. Compared with the original split type, the volume and weight of the 1/3 are reduced.Construction can still be carried out in a small on-site space.

⨠Chinese and English language switch to meet the needs of customers in different fields.

⨠Integrated structure design, for the construction of small space on site.

⨠10-inch Chinese (English) interface, graphical operation interface, built-in expert parameters, provide powerful user data and

system parameters, easy operation makes programming simple.

⨠AC 220V 50Hz/60Hz single-phase power supply, the use of switching power supply for the system module to provide voltage and

current, even in the external grid 20% range Internal fluctuations, can still ensure the repeatability of the weld.

⨠Built-in micro free maintenance printer, no need to change ink cartridges, one-button printing and automatic printing function.

⨠Fault protection function, automatic diagnosis function and maintain fault alarm information, reduce the electrical damage caused

by misoperation.Parameter adjustment Memory save function.

⨠The parameter partition function can fine-tune the parameters of each interval to achieve the best welding effect.

⨠Adopting customized high pulse DSP modules for precise control and sampling of various output parameters.

tank, which has the characteristics of digitization, easy operation and reliability. The control system adopts an open and upgradeable operating system to centrally set, store and synchronize the various functional parameters in all-position welding.This power supply is specially designed and manufactured for thin-walled tube/tube welding. Mainly used in semiconductor,chemical, food, medicine, electronic pipeline and other industries.The overall design tends to be convenient,energy-saving,intelligent, human-computer interaction. Compared with the original split type, the volume and weight of the 1/3 are reduced.Construction can still be carried out in a small on-site space.

⨠Chinese and English language switch to meet the needs of customers in different fields.

⨠Integrated structure design, for the construction of small space on site.

⨠10-inch Chinese (English) interface, graphical operation interface, built-in expert parameters, provide powerful user data and

system parameters, easy operation makes programming simple.

⨠AC 220V 50Hz/60Hz single-phase power supply, the use of switching power supply for the system module to provide voltage and

current, even in the external grid 20% range Internal fluctuations, can still ensure the repeatability of the weld.

⨠Built-in micro free maintenance printer, no need to change ink cartridges, one-button printing and automatic printing function.

⨠Fault protection function, automatic diagnosis function and maintain fault alarm information, reduce the electrical damage caused

by misoperation.Parameter adjustment Memory save function.

⨠The parameter partition function can fine-tune the parameters of each interval to achieve the best welding effect.

⨠Adopting customized high pulse DSP modules for precise control and sampling of various output parameters.

|

Technical parameters

|

|||

|

Model

|

ET200/M200 Digital programmable power supply

|

||

|

Current input(V)

|

220V ± 10% (AC)

|

Current output (A)

|

5-200A(DC)

|

|

No-load voltage (V)

|

65

|

Power(KVA)

|

4.5

|

|

Temporary load rate

|

|||

|

Current input

|

Average output

|

Temporary load rate

|

|

|

220V/16A

|

200A

|

60%

|

|

|

220V/16A

|

150A

|

100%

|

|

|

Other

|

|||

|

Protective gas

|

argon

|

Cooling method of welding gun

|

water-cooling

|

|

Overall dimension(mm)

|

500x380x300

|

Weight (KG)

|

27 (Including 2.2L cooling water)

|

|

control mode

|

PLC

|

Store parameters

|

200 Groups

|

|

Welding section

|

Optional 12

|

Protection class

|

IP21

|

|

Function control

|

Current Control, Gas Control, Rotary Control,Printing control, Water cooling control

|

||

|

Safety functions

|

Over-voltage, overload, leakage, arc failure, tungsten pin short circuit protection, and defect detection

|

||

Share

Text block

Ver todos los detalles